Sandblasting is one of the most common preparatory processes in the course of powder coating or painting. Hamminger surface technology offers customers from trade and industry sandblasting on two automatic systems:

As a pre-treatment for our customers in powder coating

As contract blasting for customers who subsequently carry out painting work themselves

With over four decades of experience and in-depth expertise in the finishing of metal surfaces, we carry out sandblasting precisely and reliably for you.

Sandblasting by Hamminger surface technology

Customers of Hamminger surface technology benefit from the combination of expertise and flexibility:

ISO 9001.2015 – certification

Storage capacity for just-in-time orders

Logistics service for delivery and collection

Component sizes for steel, aluminium and stainless steel up to 1800 x 700 x 700 mm

If sandblasting is carried out as a pre-treatment for the powder coating of components, we offer assembly as an additional service. We take care of pre-assembly and packaging for you to whatever extent you require.

Sandblasting – a versatile tool

Sandblasting fulfils various functions in the course of the treatment of metallic surfaces:

- Removal of contamination (descaling, removal of weld spatter, paint, etc.)

- Removal of corrosion

- Deburring

- Roughening of surfaces

- Matting of surfaces

Sandblasting is one of the most environmentally friendly processes for cleaning surfaces, as neither chemicals nor solvents are used.

How does sandblasting work?

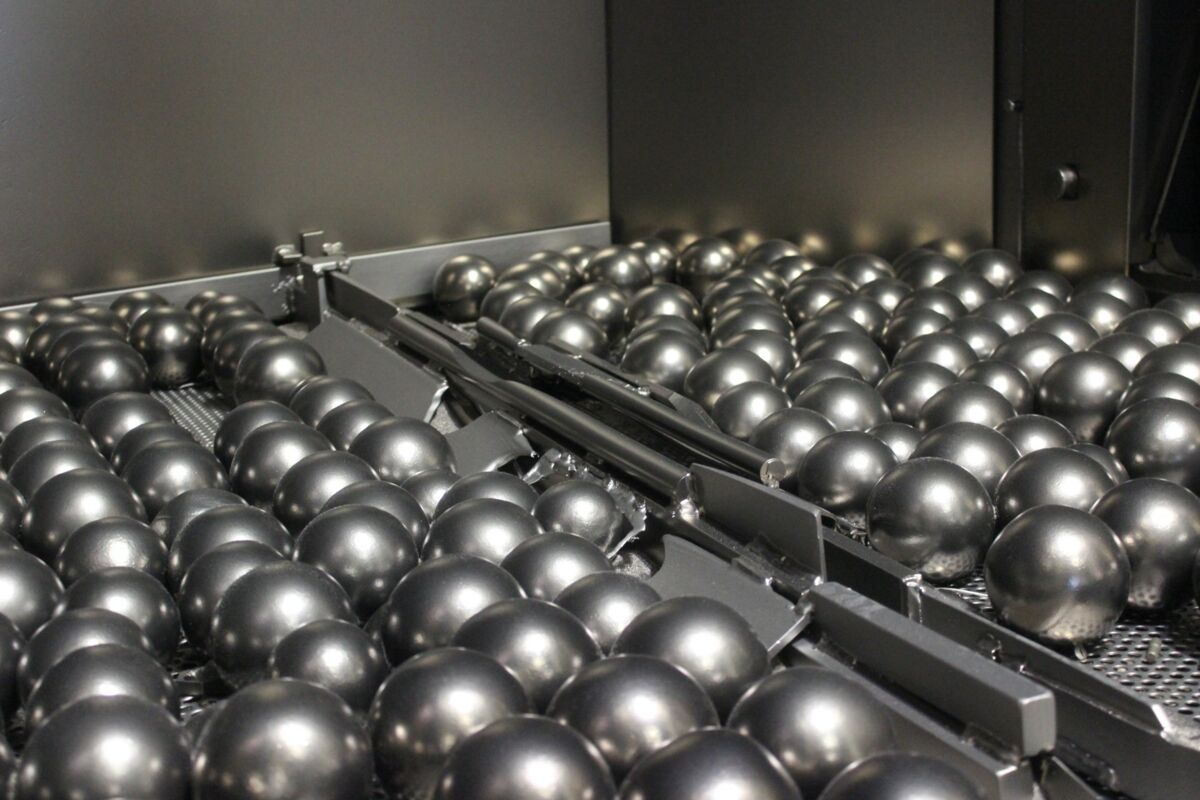

In sandblasting – also referred to as abrasive sandblasting – abrasive (rubbing, grinding) material hits the surface to be treated at high pressure and high speed. This "grinds off" impurities.

Depending on the choice of abrasive, the surface remains smooth or is roughened to the desired extent.

A wide variety of materials are used as blasting agents, depending on the surface (sandblasting takes place with wood, glass and numerous other materials). The spectrum ranges from glass granulate and glass beads to corundum and angular steel.

At Hamminger surface technology, we sandblast metal using these materials:

- For aluminium: Chrome 30 (nickel-chrome alloy)

- For steel: G50 (steel grain)